Simplify3D team had the good idea to realize this very comprehensive guide on a lot of problems. I invite you to consult it and add it to your favorites.

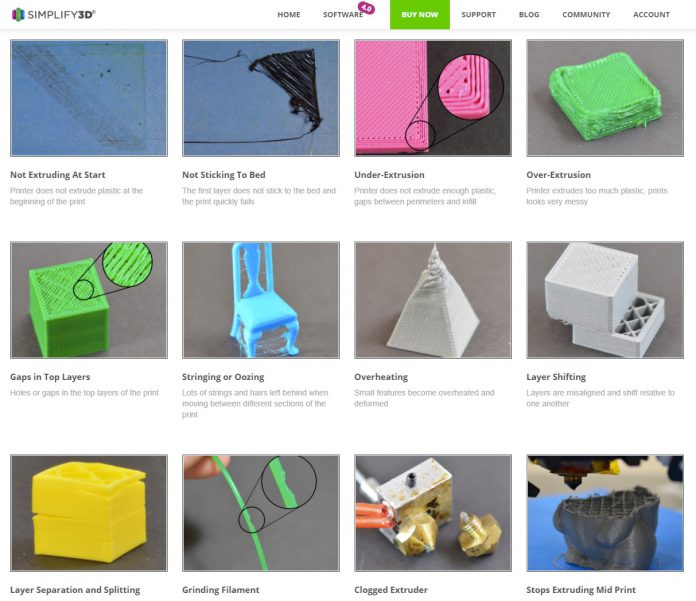

This guide is a great place to start if you are trying to improve the quality of your 3D printed parts. We have compiled an extensive list of the most common 3D printing issues along with the software settings that you can use to solve them. Best of all, the guide uses a large collection of real-world images to make each issue easy to identify when examining your own 3D printed parts. So let’s get started!

GO TO THIS TROUBLESHOOTING GUIDE

Most of troubleshooting are fix with few steps :

- Not Extruding At Start

- Not Sticking To Bed

- Under-Extrusion

- Over-Extrusion

- Gaps in Top Layers

- Stringing or Oozing

- Overheating

- Layer Shifting

- Layer Separation and Splitting

- Grinding Filament

- Clogged Extruder

- Stops Extruding Mid Print

- Weak Infill

- Blobs and Zits

- Gaps Between Infill and Outline

- Curling or Rough Corners

- Scars on Top Surface

- Gaps in Floor Corners

- Lines on the Side of Print

- Vibrations and Ringing

- Gaps in Thin Walls

- Small Features Not Printed

- Inconsistent Extrusion

- Warping

- Poor Surface Above Supports

- Dimensional Accuracy

- Poor Bridging

Here a list of greats others troubleshooting guides dedicated to ours FDM 3D printers:

- https://www.matterhackers.com/articles/3d-printer-troubleshooting-guide

- http://support.3dverkstan.se/article/23-a-visual-ultimaker-troubleshooting-guide

- http://reprap.org/wiki/Print_Troubleshooting_Pictorial_Guide

Facebook Comments