Bambu Lab has redefined the standards of high-speed 3D printing. With the arrival of the new “H2 Series,” the manufacturer is making a strong push in the professional segment. But choosing between the Bambu Lab H2D and the Bambu Lab H2S is a tough decision. They share a robust frame, a heated chamber, and precision mechanics, but their design philosophies are radically different.

Bambu Lab H2D vs H2S

Bambu Lab US Store Black Friday Sale

So, H2D or H2S? Which one should you choose? As 3D printing and rapid prototyping experts in Nice, AzurMedia breaks down these two machines for you to help you make a wise investment.

The Fundamental Difference: The Heart of Extrusion

Let’s not beat around the bush: the major difference lies in the print head. This is what defines the machine’s use and has a direct impact on the available print volume.

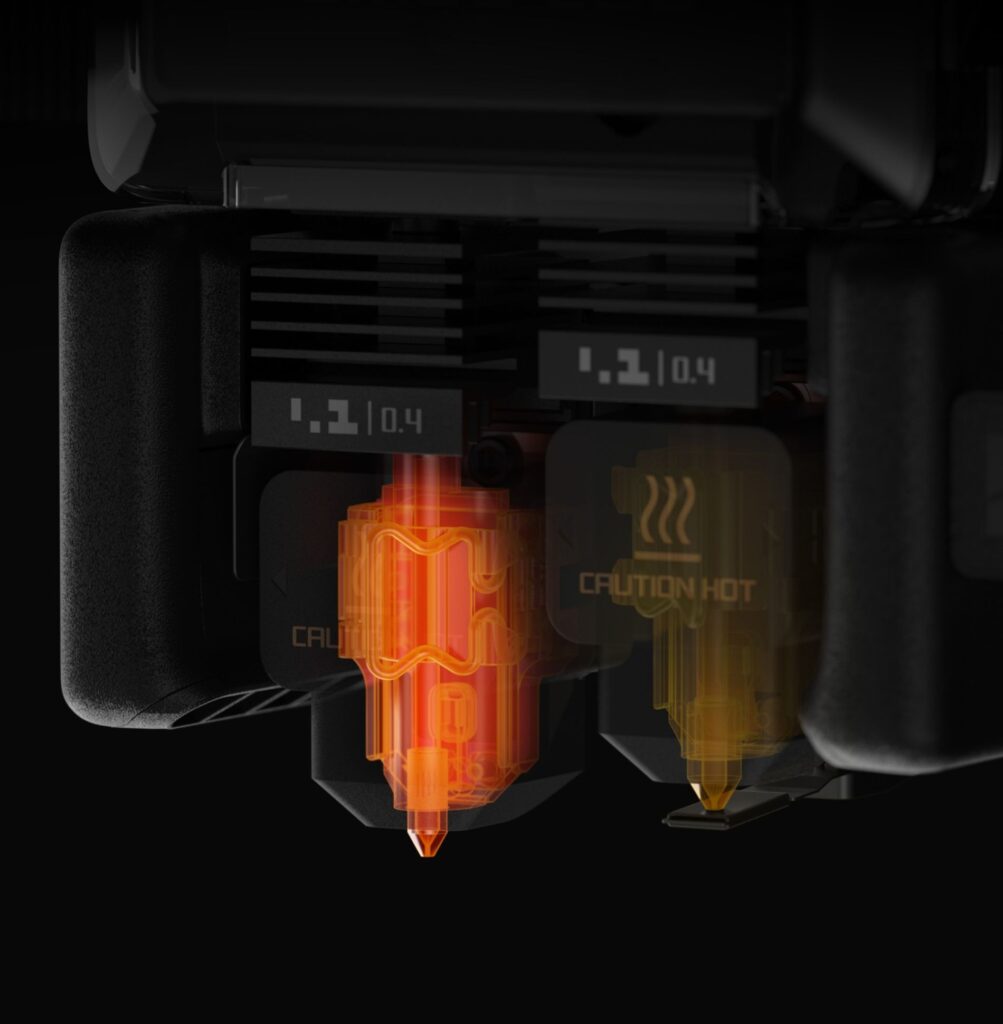

The main advantage of the H2D: The “Dual Nozzle” System

The H2D (for “Dual”) is equipped with a proprietary dual nozzle system integrated into a single print head. A sophisticated mechanism allows it to “switch” between the two nozzles by retracting the one that is not in use.

The common mistake is thinking this system is only good for two-color printing. While that’s possible (and without any purging!), its real superpower lies elsewhere: multi-material printing and soluble supports.

Imagine needing to print a complex mechanical prototype with overhangs or internal cavities. With a standard printer (even the H2S + AMS), you would use PLA as support material for PLA. Removal is difficult, leaves marks, and limits the available geometries.

With the H2D, you print your part in PETG or Nylon, and the supports with a soluble filament (like PVA or BVOH). Once the print is complete, simply immerse the part in water: the supports melt, leaving a perfect, flawless piece. This is essential for functional prototyping and aesthetically pleasing parts.

The strength of the H2S: Volume, Speed, and Simplicity

The H2S (for “Single”) takes a different approach. It has a single nozzle, but optimizes everything else. Its print head is simpler, lighter, and frees up more workspace.

It is designed to be a true workhorse: the rapid and reliable production of single-material parts. It remains compatible with Bambu Lab’s AMS for multi-color printing, but will suffer the classic drawbacks of purging (wasted filament and additional time) with each color change using this method.

The Logical Consequence: Print Volume

This difference in print head has a direct impact on the maximum build volume. The more compact head of the H2S allows it to offer more space, especially vertically.

- Bambu Lab H2S (Single Nozzle): Offers a maximum build volume of 340 x 320 x 340 mm.

- Bambu Lab H2D (Dual Nozzle): Its build volume is 325 x 320 x 325 mm (in single nozzle mode) and is slightly reduced on the X-axis (300 mm) when using both nozzles.

The H2S therefore offers you 15 mm more height, which can be crucial for very large parts printed in a single piece.

Comparison: Advantages and Disadvantages

Bambu Lab H2D (The Versatile Technician)

Advantages:

-

- ✅ Soluble Supports: The number one advantage for complex and clean parts.

- ✅ True Multi-Material: Ability to mix materials (e.g., rigid PLA body + flexible TPU hinge) in a single print.

- ✅ Zero Waste: No purge towers in dual-color or dual-material mode.

Disadvantages:

-

-

- ❌ Price: Significantly more expensive to purchase.

- ❌ Complexity: More maintenance and calibration required (managing two nozzles).

- ❌ Reduced Volume: The print volume is slightly smaller than that of the H2S.

-

Bambu Lab H2S (The Production Beast)

Advantages:

-

-

- ✅ Price: Much more affordable, excellent volume/price ratio.

- ✅ Large Max Volume: The largest volume in the H2 series (340 mm Z-axis).

- ✅ Simplicity: Easier to maintain (single nozzle).

- ✅ Lightweight nozzle: Optimized for pure speed in single-material printing.

-

Disadvantages:

-

-

- ❌ No soluble supports: Limiting for very complex geometries.

- ❌ Multi-color (via AMS): Involves filament waste and purging time.

- ❌ No true dual-material printing: Impossible to mix PLA and TPU, for example.

-

Practical Advice: Which one to choose based on your profile?

As prototyping professionals, here is our opinion on the ideal profile for each machine.

Profile 1: The Engineer, the Design Office, Functional Prototyping

➡️ Choose the H2D.

If your job involves designing mechanical parts, complex enclosures, functional prototypes, or assembly jigs, the ability to use soluble supports is not a luxury, it’s a necessity. The time saved in post-processing and the quality of the final parts justify the investment. You need the versatility of the dual nozzle.

Profile 2: Rapid Prototyping, Small Series Production, Large Format Printing

➡️ Choose the H2S.

If you primarily print large parts, architectural models, or perform rapid prototyping in a single material (shape validation), the H2S is unbeatable. It’s a reliable, fast production machine with a large build volume. You save a considerable amount of money that you can invest in filaments or an AMS.

What if you didn’t have to choose? The AzurMedia alternative

You already own an H2S (or another printer) but you have an occasional printing need with additional support Soluble ports? Or conversely, do you have an H2D printer but need to quickly produce 50 pieces?

Buying a machine costing over €1500 is an investment. At Printer3D.one, we believe in the right tool for the job.

Focus on your business; we’ll take care of the manufacturing.